Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

EMCO Wheaton’s additive system is designed for road tankers and is mainly used when delivering fuel for domestic heating purposes.

Additive injection helps customers achieve a cleaner burn, improved performance and fewer maintenance problems. Most important of all, our system is efficient, safe and accurate, allowing operators to deliver without exposure to harmful chemicals.

Additives are designed to increase the efficiency of home heating oil. They also protect heating oil boilers and prolong the working life of an oil storage tank. Our additive system can be retrofitted in both the DataPlus MKII 400 pumping system and the DataPlus MKII 800 pumping system as well as competitor systems or a non-metering system.

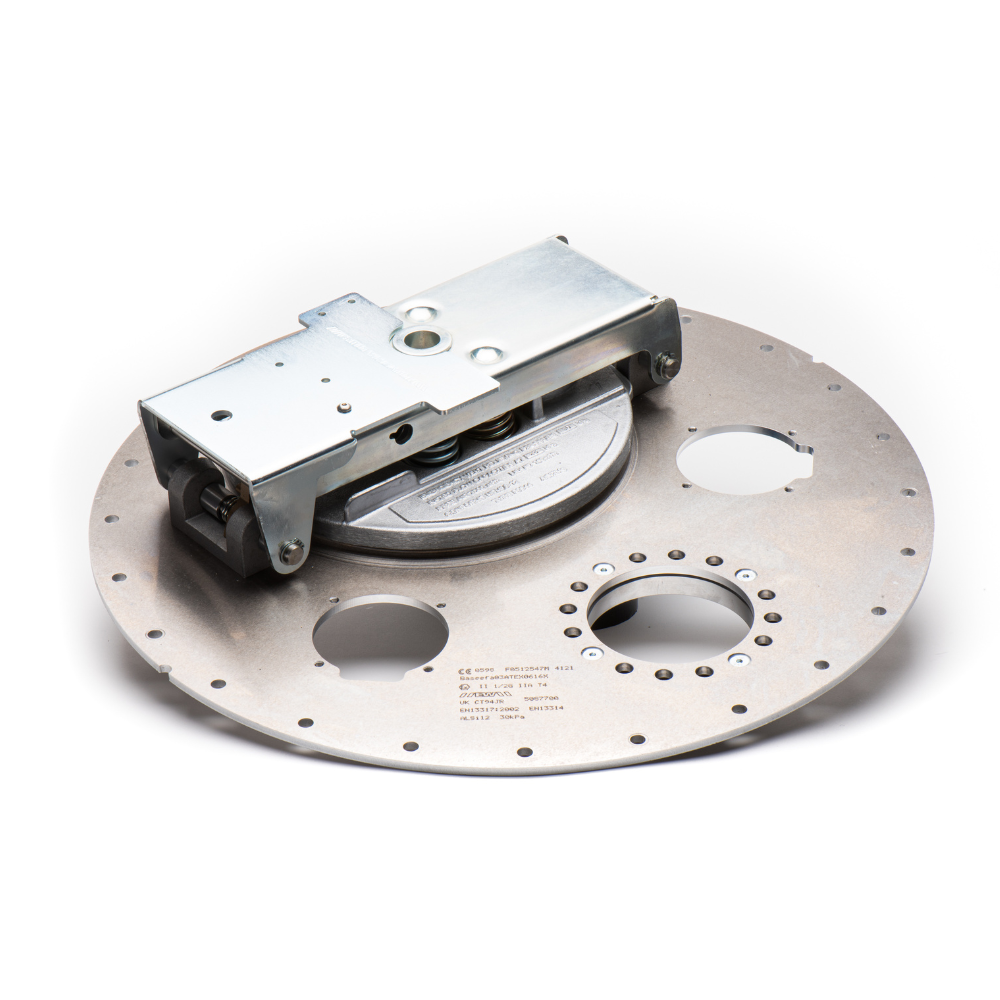

The system consists of a dosing chamber and bracket, two or more capacity chambers, bottle adapter, an additive injection valve, chemical-resistant hydraulic hose and hose unit, and a control system depending on the application.

Unlike competing systems that opt for injection on the vacuum side, EMCO Wheaton’s design adds 100ml of solution per system cycle through a valve that’s located after the meter. This is done to guarantee accurate fuel delivery and avoid discrepancies that can add up over time. Delivery is initiated and controlled by either an electronic litre counter display or a manual pneumatic control unit.

The valve is based on the Venturi effect. When deliveries do not require additive, the system remains in an ‘open’ state with no restriction to flow. Flow rate will only drop temporarily at the point when an operator adds solution to the mix – this last roughly six seconds. Once complete the valve opens again so flow can continue unimpeded.

In line with health and safety recommendations from COSHH, EMCO Wheaton’s additive system can also incorporate an adapter unit to limit operator contact with the solution. For larger bulk deliveries, the additive system offers a 20-litre storage tank option. Smaller jobs can be completed with our capacity chambers in 1.2-litre and 3-litre containers.

The system is designed to operate between -20°C to +50°C and has a total kit weight of 18kg. EMCO Wheaton supplies all the necessary bracketry for installation.

The dosing chamber will introduce 100ml of additive for every 500 litres of fuel. This is done at the beginning to ensure a good mix of solution throughout, even when delivering larger quantities.

This product is designed for use on fuel oil carrying road tankers, delivering to storage containers for home heating systems. However, it can also be used for bulk deliveries .

This product is designed to be durable and has few moving parts.

However, fuel delivery is an intensive process and equipment occasionally requires maintenance to remain in optimal condition.

That’s why EMCO Wheaton has a team of expert service engineers on hand to troubleshoot any problems you may have. Simply call the support line to speak with a member of the team.

ABOUT EMCO WHEATON

For more than 100 years, Emco Wheaton has provided premium fluid transfer systems that are engineered t omeet and exceed the growing demands of our customers across a range of on- and off-shore industries; including gas, chemical, aviation, storage and transportation. We take pride in servicing a global customer base by offering a range of market leading loading and fuel systems that have been engineered using extensive experience, expertise, and a culture of innovation. Backed by our first class service and support, only Emco Wheaton can provide our customers with the quality, safety, and peace of mind needed to help them drive their operations into the future.